REVOLUTIONIZING ROOFING

Explore polymer modified options

REVOLUTIONIZING ROOFING

Explore polymer modified options

we use polymer modified on our own homes

Polymer modified roofing is a type of roofing membrane that incorporates polymers into the asphalt base material. This addition enhances the roofing material’s overall performance and durability. Polymers, such as styrene-butadiene-styrene (SBS) or atactic polypropylene (APP), improve the roofing membrane’s flexibility, resistance to temperature extremes, and resistance to UV radiation.

What is polymer modified roofing?

Polymer modified roofing is a type of roofing membrane that incorporates polymers into the asphalt base material. This addition enhances the roofing material’s overall performance and durability. Polymers, such as styrene-butadiene-styrene (SBS) or atactic polypropylene (APP), improve the roofing membrane’s flexibility, resistance to temperature extremes, and resistance to UV radiation.

Polymer modified roofing systems offer several advantages over traditional asphalt roofing. They are more resistant to cracking and tearing, especially in harsh weather conditions. They also have a longer lifespan, reducing the need for frequent replacements. Additionally, polymer modified roofing systems are more energy-efficient, helping to lower energy costs. They can also be applied in a variety of ways, including torch-applied, self-adhered, and mechanically attached, making them suitable for various roofing projects.

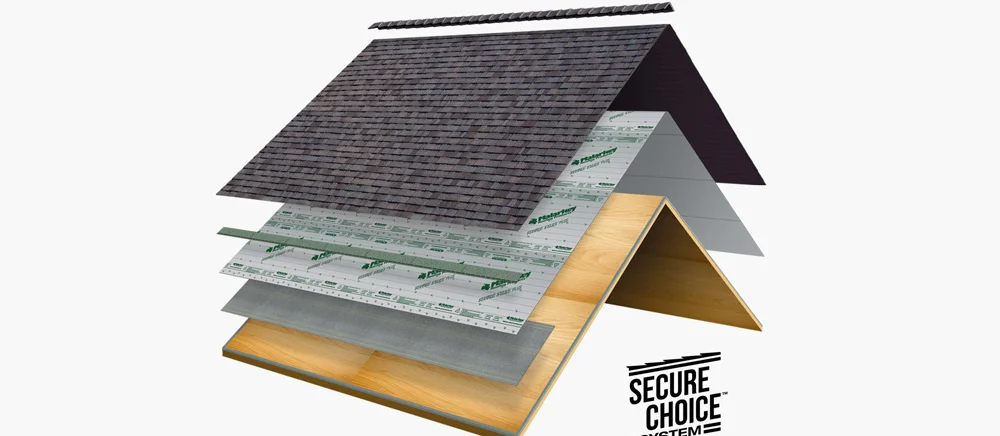

Sys•tem: noun

a set of things working together as parts of a mechanism or an interconnecting network.

ROOF SYSTEM COMPONENTS:

1. DECKING

Decking provides the main support for your roof components. It is the backbone. It is critical to have sound decking for a proper roof build – no rot or soft spots.

The roof decking we use today is typically done with 4’x8′ panels of OSB (oriented strand board) – made from heat cured adhesives and small rectangular shaped wood strands. These panels provide structural support and distributes the weight of the roof evenly across the underlying framework.

2. ICE & WATER SHIELD

Ice and water shield is a vital component of roofing systems, especially in regions that experience cold climates and heavy precipitation. It is a self-adhesive membrane that provides protection against water infiltration caused by ice dams, wind-driven rain, and other forms of moisture.

While code varies from county to county, Locke & Ladder uses ice barrier in all eaves, valleys, along walls, around chimneys, any penetrations, and slopes less than 4/12 pitch.

3. SYNTHETIC UNDERLAYMENT

Underlayment is installed directly onto the roof deck before the final roofing material (such as shingles, tiles, or metal panels) is applied. It acts as a secondary layer of defense against water penetration. Even with a properly installed roof covering, there is always a possibility of wind-driven rain or ice damming causing water to infiltrate beneath the roofing material. Underlayment provides an additional barrier that helps to prevent water from reaching the roof deck, protecting it from moisture damage, rot, and leaks.

Importance of Synthetic Underlayments

Synthetic underlayment is typically made from polypropylene or other synthetic materials, making it highly resistant to tearing, puncturing, and UV damage. It offers greater durability and longevity compared to traditional felt underlayment, which can degrade over time.

The choice of underlayment should align with the specific requirements of the roofing system, local building codes, and the manufacturer’s recommendations. Proper installation and adherence to industry best practices ensure the underlayment performs effectively and provides the desired level of protection for your roof.

4. STARTER SHINGLES

Starter shingles, also known as starter strips or starter courses, are placed at the eave and rake edges of your roof. They are crucial for :

+ Proper alignment and aesthetics

+ Protection against wind uplift

+ Waterproofing, leak prevention, and moisture migration

+ Increased roof longevity

+ Warranty compliance

Locke & Ladder employs the Smart Start™ starter shingle – made with Malarkey’s NEX® Polymer Modified Asphalt and high-grade, rubberized adhesive for exceptional seal-down.

5. FIELD SHINGLES

Roofing or field shingles are like the armor that shields your home from the harsh elements. They act as a barrier against rain, snow, hail, wind, and the scorching sun. But they can also do so more…

With the right shingle you gain style, color, character, lower insurance premiums*, and a high probability you’ll survive the next hail storm.

Malarkey’s Vista®, Legacy™, and Windsor® shingles are Class 4 rated (highest rating possible) for impact by UL, and meet IBHS FORTIFIED™ Roof requirements. As a result, these shingles often qualify for insurance discounts.

*based on carrier and class rating.

6. HIP AND RIDGE SHINGLES

Hip and ridge shingles are designed specifically for the areas where roof slopes meet or intersect.

Ridge – the horizontal line formed by the intersection of two roof slopes. Runs parallel to the eaves of the roof.

Hip – extends diagonally from the eaves towards the peak of the roof.

Hip and ridge shingles differ from standard shingles in their shape and purpose. They are often narrower and have a modified shape, such as a three-tab design or a specifically designed ridge cap shingle. These shingles are flexible and can be easily bent or shaped to fit the contours of the roof’s hips and ridges.

Re-Thinking Roofing

Roofing dates back to the earliest of and most basic of human needs. Essential for refuge. This is why Locke & Ladder has researched, analyzed, and scrutinized every aspect of what makes a high performance roofing system.

Chat with us about how to achieve a complete and lasting system for your home.